3D Fibreglass Fabric

Endless possibilities with 3D E‑glass fabrics

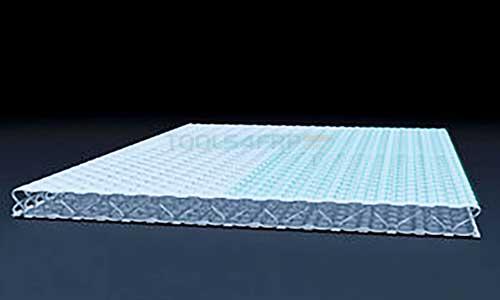

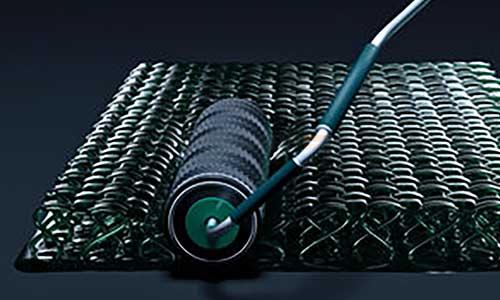

The goal of excellent composite manufacture and assembly is to make them light, durable, rigid, and cost-effective. All of these challenges are addressed with Parabeam 3D Fibreglass Fabric. Parabeam 3D glass fabrics are woven from E-glass yarn to allow for the rapid and easy manufacturing of high-quality sandwich constructions. Vertically braided 8-shaped pillars connect two bi-directionally woven deck levels. The pillars function as springs, pushing the deck layers apart to a certain height. This sturdy and lightweight sandwich structure outperforms standard sandwich textiles, as well as wood and laminate materials.

Application Instructions

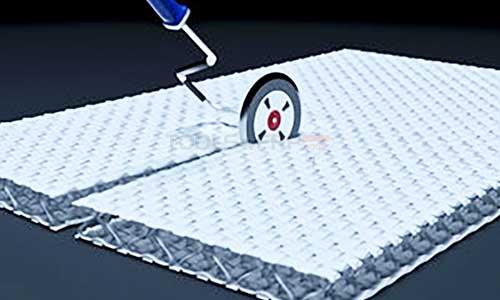

The four methods of creating the finished product are: hand lay-up, vacuum infusion, closed mould and inline product.

Measure the surface of the fabric & calculate fabric weight. Fibre-resin ratio ranges between 1:1.1 &1:1.2. A low styrene emission (LSE) is recommended.

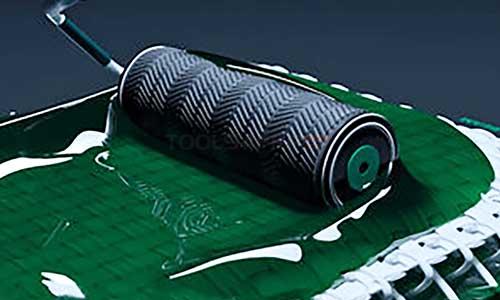

Apply 40% of the calculated resin to the mould and spread it evenly.

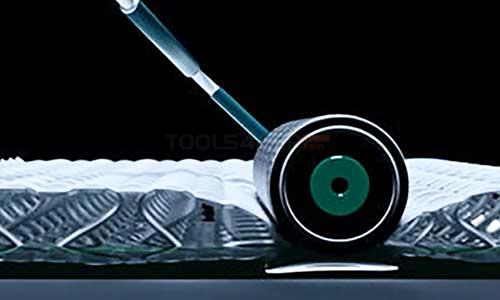

Roll fabric to ensure that resin is distributed evenly. De-airing is not necessary as air is thin and will escape from all sides.

Products

No matter what the industry or product, there is only one thing that limits how ParaGlass and ParaTank can be used – imagination.

Product Name

Description

Product Name

Description

Applications

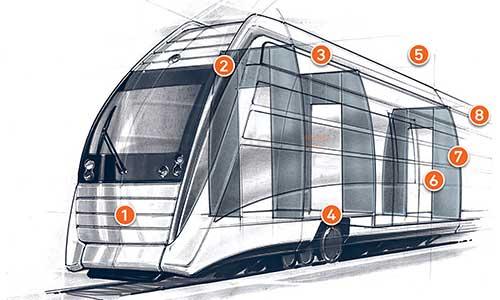

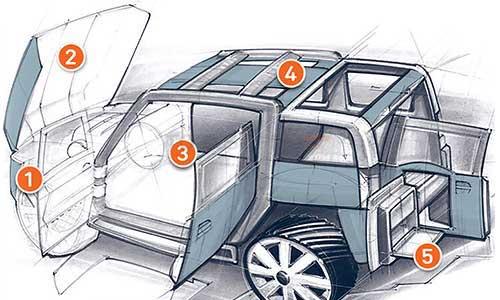

ParaGlass proves its versatility as a sustainable solution in all forms of ground transportation. Its favorable weight-to-strength ratio and high FST (fire, smoke, toxicity) properties make it easy for companies to meet carbon footprint requirements in mass transportation and individual vehicles. This makes it extremely valuable when manufacturing parts for electric vehicles.

Resistant to decay, fungi and algae, ParaGlass is applied as the primary core for floor heating in trains and busses. In tropical areas, it is used in condenser systems for air-conditioned metro and train carriages. More economical and lightweight as a secondary core than honeycomb, it is often used as a sound and temperature insulator in rail cars. It can also be used as cladding when refurbishing trains.

1 Nose cone

2 Endcap and side panels

3 Ceiling panel interior (core)

4 Floor panel (lightweight core) and heated-floor system

5 Air-conditioning condenser

6 Door (secondary core) and door panel

7 Section divider and bulkhead

8 Toilet cabin

1 Spoiler and air deflector

2 Hood (core material)

3 Seat (flexible core material)

4 Complete roof structure

5 Storage boxes

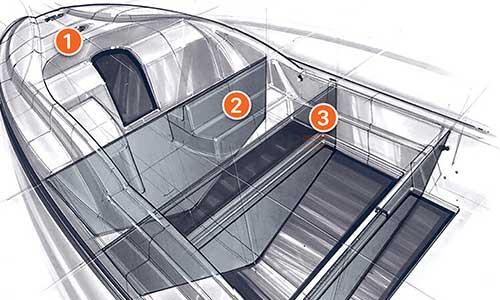

Resistant to humidity and corrosion, ParaGlass offers many advantages in marine vessels. It is highly drapeable, and bonds well with other construction materials, such as wood, foam, steel and aluminum. Its high insulation properties adds value in any type or size of watercraft.

ParaGlass is stronger the plywood, less costly than teakwood, and lighter and easier to apply than honeycomb. With a one-step lamination process that saves labor time and cost, it is commonly used in flybridges, swimming platforms and engine covers, as well as areas shown here.

2 Flooring

3 Cabinets

4 Ceiling panels

1 Decks

2 Seating

3 Interior panels