U-Pica Mat

U-PICA MAT has been developed jointly by Toyobo Inc. Toyao Cloth Co., Ltd. nd Japan U-Pica Co., Ltd. as a laminate bulker/print control mat in order to provide remarkable workability, cost and weight advantages, and reduce the telegraphing or print-through of other reinforcements in FRP laminates.

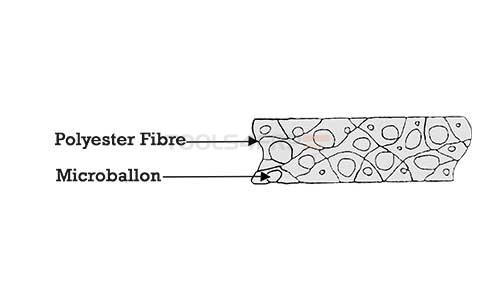

U-PICA MAT is a low-density, non-woven continuous-strand laminate bulker/print mat containing approximately 45% by volume of microballons and having a density of 0.045 g/cm3 .

U-PICA MAT has an excellent wet-out property for unsaturated polyester resin and absorbs 55% by volume of the resin. No change in the thickness of U-PICA MAT is observed even after the resin has been cured, if an appropriate quantity of the resin is impregnated into U-PICA MAT.

Features

U-PICA MAT provides a better core layer in mechanical properties than those of conventional core materials to FRP laminates after the resin has been cured, because it can be impregnated of 55% by volume into U-PICA MAT. As a result, U-PICA MAT gives many advantages in physical properties to FRP laminates as one of core materials.

When the property of U-PICA MAT laminate is compared with that of solid FRP having the same flexural strength as the laminate

- U-PICA MAT is lighter

- The quantity of the resin required can be generally decreased, and thus reducing the cost.

U-PICA MAT laminate easily provides the formation of thick core layer, and greater stiffness. It is, therefore,

suitable for use in thin and complex laminated parts where rigidity and light weight are required.

U-PICA MAT laminate provides excellent impact strength and superior thermal insulation, because it contains microballoon.

U-PICA MAT has several following advantages in workshop:

- Useful to save on the amount of glass mat and then the resin required

- Decreases laminating time, particularly in thick structures

- Decreases exotherm, and as a result easily provides thick laminate

Products

Code

Thickness

Weight

Roll Width

Qty / Roll

Applications

- In ships and boats ( hull, decks, roofs, bridges and other riggings)

- For motor vehicles ( spoiler, fenders, roofs, container panels, etc)

- For housing ( bathroom units, water tanks, septic tanks, drain lids, floor lining, swimming pool, etc)

- Others ( crawls, feed tanks, moulds, etc)

U-PICA MAT provides cost and weight advantages and an increase in stiffness in FRP laminates

U-PICA MAT for back up laminate is limited to in case where no tensile stress is directly generated to U-PICA MAT layer, Sandwiched structure is recommended, if a little stress is directly generated to U-PICA MAT layer

When U-PICA MAT laminate is used for products in which corrosion resistance is required, it is desirable to avoid exposing U-PICA MAT laminate directly to corrosive materials

U-PICA MAT can be widely used for many applications of marine field, because it has been approved by Lloyd’s