Fibreglass Chopper Spray

Fibreglass Chopper Spray

Fibreglass Chopper Spray is an obvious choice for automation when one wishes to advance from hand lay-up process. The ZS 650 is a comprehensive solution that gives high output, operational ease and economical upkeep. Equipment comes with catalyst pump that works as a slave of resin/gelcoat pump of 11:1 ratio. Air manifold with individual pressure controls make it easy to operate and provides flexibility to adjust the systems as per raw material.

Spray gun is light weight, easy to operate and clean. Options of various spray tips are available to suit resins and gelcoats with vide viscosity range. Spraying filled resin is absolutely stress-free. Tip rotational system (360°) allows operator to change the spray pattern in seconds from vertical to horizontal. Comes with a unique instant-start catalyst system. Spray works on air atomization concept. Fibreglass roving chopper is mounted over the spray gun. Separate on/off slide switch is provided on chopper unit. This is very useful to stop spray of roving and use system only to wet-out.

Roving brake, ceramic guides and rack for two bobbins are incorporated on the structure. Equipment is mounted on a bi-directional movement cart with extended arms that can move is all four directions.

Product Code

ZS 650

Handy Chopper Gun

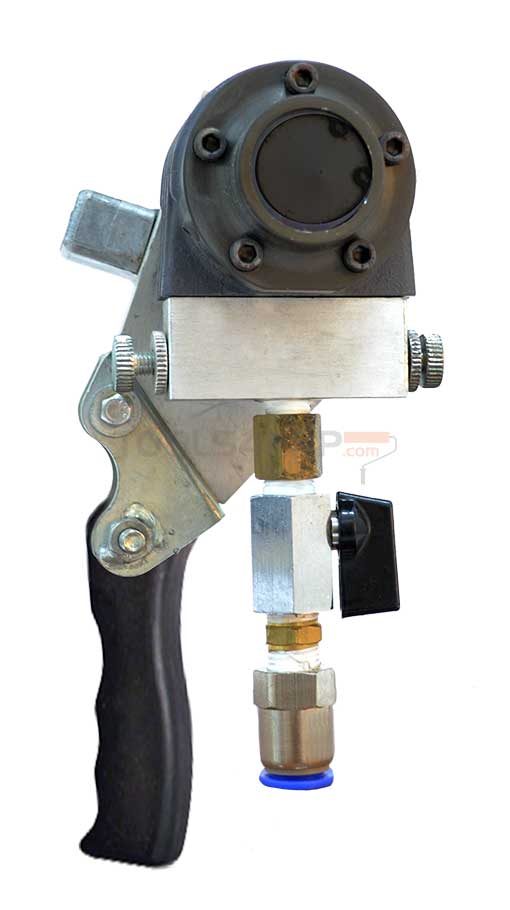

Handy Chopper Gun automatically chops and deposits fiberglass chop (assembled) roving strands or carbon tow strands onto a mould or composite parts or chopped strands may be collected in a bag / box. This user friendly tool is light weight and easy to handle. It quickly covers large surfaces with fiberglass strands.

End of chop roving are fed into the guide slots provided at top of the gun from long continuous spools. With a set of adjustable blade assembly, size of strand can be controlled to achieve chop lengths of 12 mm, 25 mm or 50 mm; with a tolerance of +5 mm. Air flow control knob allows you to vary the speed of motor and hence output volume of chopped strands.

Product Code

Cutting Output for an hour (60 minutes)