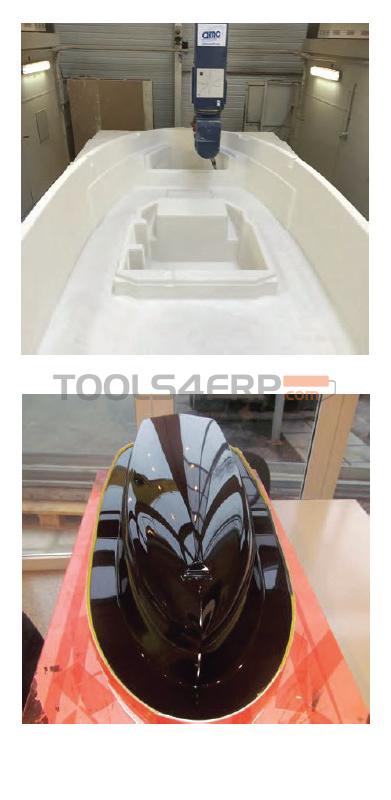

Pattern Finishing

Carefully selected raw materials for tool making is most important. Pattern (master) will reflect on your mould (tool) and mould will reflect on all your parts.

Filling polyester primer coat, applied as first layer over wooden, plaster or PU board master. Easy to use and allows high sand-ability. Leaves no porosity, give high impact resistance and is fast curing. Consumption on MDF plug shall be ± 600 gr/m2.

Ready to use, polyester primer coat. Has great adhesion on metal, polyester and wood substrates. Comes with short gel time and fast cure. Imparts glossy finish, consumption on MDF plug shall be ± 600 gr/m2.

Ready to use, polyester primer coat. Has great adhesion on metal, polyester and wood substrates. Comes with short gel time and fast cure. Imparts glossy finish, consumption on MDF plug shall be ± 600 gr/m2.

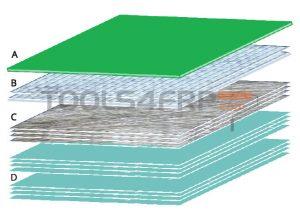

Mould Conception

A. Face-Coat:

Use low shrinkage Gelcoat to create layer thickness of 0.6 ~ 0.8 mm.

B. Skin-Laminate:

1 layer of 30 gr/m2 CreVeil, surface tissue with low shrinkage tooling resin.

1 layer of 150 gr/m2, low tex mat with low shrinkage tooling resin.

2 layers of 300 gr/m2 powder mat with low shrinkage tooling resin.

Create a thickness of Skin-Laminate between 1.6 ~ 1.8 mm.

C. Intermediary:

3 layers of 450 gr/m2 powder mat with low shrinkage tooling resin.

Create a thickness of Intermediary between 2.4 ~ 2.6 mm.

D. Structural:

1 layer of 450 gr/m2 powder/emulsion mat with laminating resin.

1 layer of U-Pica Mat, T-3000 with laminating resin.

1 layer of 450 gr/m2 powder/emulsion mat with laminating resin.

1 layer of U-Pica Mat, T-3000 with laminating resin.

1 layer of 450 gr/m2 powder/emulsion mat with laminating resin.

Create a thickness of Structural between 8.5 ~ 9.5 mm.

Tooling Gelcoats & Resins

Vinyl Ester Chemistry

Tooling gelcoat is formulated from epoxy bisphenol A resin. Perfectly suited in production of FRP moulds for open and closed moulding processes. Mould will have properties like substantial gloss retention, resistance to splitting, stability at high temperature.

Tooling resin is engineered to suit diverse requirement of FRP moulding. It provides wet-out, easy air release, low shrinkage and higher heat deflection temperature.

Isophthalic Chemistry

Isophthalic gelcoat & resin for tooling application shows excellent wetting and low shrinkage. Mould made with this system exhibits smooth and glossy surface finish, improved weather resistance and hydrolytic stability.