Metering-Mixing-Dispensing System

Roberto MMD

Metering-Mixing & Dispensing system allows an economical use of raw materials. Semi-automated operation and easy maintenance. Ideal for large factories and high-volume production.

Technical Specifications

Product Code

Roberto MMD

Pulfrusion

Filament Winding

Hand Layup

Recirculation

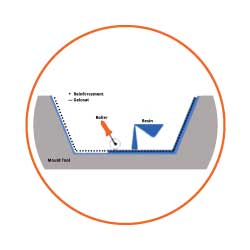

Unmixed resin and catalyst to cycle from dispense head back to reservoir. Two liquids can be recirculated individually without mixing. This allows material lines to remain de-gassed without wastage. Constant movement of material prevents settling of fillers.

Solvent & Air Purge

Immediate cleaning and drying of dispense head is easily operated via SAP controls mounted on the user panel. Independent solvent flush prevents curing of resin within the mix and dispense head. Separate air flush and drier ensures quick and efficient cleaning.

Positive Feed Slave Pump

Catalyst pump works as a slave with resin pump. Catalyst-to-resin percentage can be adjusted quickly without any tool. Percentage can be varied between 0.5% to 3.25%.

Feed Tanks

Stainless Steel pressure feed tank for solvent & individual storage bottle for catalyst.